Are you curious about how to control stepper motors with Arduino? Stepper motors are essential in many applications, from robotics to precision machinery, due to their ability to offer precise control over movement. If you're looking to harness the power of stepper motors for your projects, Arduino provides a user-friendly and efficient platform for doing just that. This guide will walk you through the fundamentals of controlling stepper motors with Arduino, offering insights and detailed instructions to get you started on your projects.

Arduino, a popular open-source electronics platform, is favored for its simplicity and versatility. When combined with stepper motors, it opens up a world of possibilities for creating intricate and precise mechanical systems. Whether you're a hobbyist, a student, or a professional, understanding how to control stepper motors with Arduino can significantly enhance the scope and execution of your projects. The process involves programming, wiring, and understanding the dynamics of stepper motors, all of which we will cover in depth in this article.

In the sections that follow, we will explore various aspects of controlling stepper motors with Arduino, including the types of stepper motors, interfacing techniques, programming strategies, and troubleshooting tips. Additionally, we will discuss advanced topics such as microstepping and feedback control systems, which can further refine the control and precision of your stepper motor applications. By the end of this guide, you will have the knowledge and confidence to implement stepper motor control in your own projects, leveraging the power of Arduino to its fullest potential.

Table of Contents

- Understanding Stepper Motors

- Types of Stepper Motors

- Basic Principles of Stepper Motor Control

- Introduction to Arduino

- Interfacing Stepper Motors with Arduino

- Programming Stepper Motors Using Arduino

- Stepper Motor Libraries for Arduino

- Power Supply Considerations

- Troubleshooting Common Issues

- Advanced Control Techniques

- Applications of Stepper Motors

- Safety Precautions

- Frequently Asked Questions

- Conclusion

Understanding Stepper Motors

Stepper motors are electromechanical devices that convert electrical pulses into precise mechanical movements. Unlike conventional motors, which rotate continuously, stepper motors move in discrete steps, allowing for fine control over the motor's position. This characteristic makes them ideal for applications requiring precision and repeatability.

A stepper motor consists of a rotor and a stator. The rotor, typically a permanent magnet or a soft iron core, rotates within the stator, which contains multiple coils. By energizing these coils in a specific sequence, the rotor moves incrementally, completing a full rotation in a series of steps. The number of steps per revolution, or step angle, varies depending on the motor design, with common step angles being 1.8 degrees for 200-step motors and 0.9 degrees for 400-step motors.

Stepper motors are classified into two main types: unipolar and bipolar. Unipolar stepper motors have a center-tapped winding for each phase, allowing for simpler control circuits. Bipolar stepper motors, on the other hand, have a single winding per phase, requiring more complex control circuitry but offering higher torque and efficiency. We'll delve deeper into these types in the next section.

Types of Stepper Motors

There are various types of stepper motors, each with unique characteristics and applications. The two primary types are unipolar and bipolar stepper motors. Understanding their differences is crucial for selecting the right motor for your project.

Unipolar Stepper Motors

Unipolar stepper motors have a center-tapped winding for each phase, allowing current to flow in only one direction through each half of the winding. This configuration simplifies the control circuit, as it requires only four transistors to drive the motor. Unipolar motors are typically easier to use but may offer less torque compared to their bipolar counterparts.

Bipolar Stepper Motors

Bipolar stepper motors have a single winding per phase, with no center tap. To reverse the direction of current flow, an H-bridge circuit is required for each winding. While this increases the complexity of the control circuit, bipolar motors generally provide higher torque and efficiency. They are well-suited for applications requiring more power and precision.

Hybrid Stepper Motors

Hybrid stepper motors combine the features of permanent magnet and variable reluctance stepper motors, offering improved performance and precision. They typically have a smaller step angle, higher torque, and better accuracy, making them suitable for demanding applications.

Basic Principles of Stepper Motor Control

Controlling a stepper motor involves sending a sequence of electrical pulses to the motor's coils, causing it to rotate in discrete steps. The direction, speed, and position of the motor can be controlled by adjusting the order and frequency of these pulses.

There are three main driving methods for stepper motors: full-step, half-step, and microstepping. Full-step driving energizes two coils at a time, providing maximum torque but limited resolution. Half-step driving alternates between energizing one and two coils, offering a balance between torque and resolution. Microstepping, the most advanced method, gradually changes the current in the coils, resulting in smoother motion and increased resolution.

Introduction to Arduino

Arduino is an open-source electronics platform based on easy-to-use hardware and software. It is widely used for prototyping and developing interactive projects, thanks to its flexibility and ease of use. The Arduino board consists of a microcontroller, input/output pins, and a USB interface for programming and communication.

With its extensive library of resources and community support, Arduino is an excellent choice for controlling stepper motors. Its programming environment, based on C/C++, allows users to write and upload code to the microcontroller, enabling precise control over the stepper motor's operation.

Interfacing Stepper Motors with Arduino

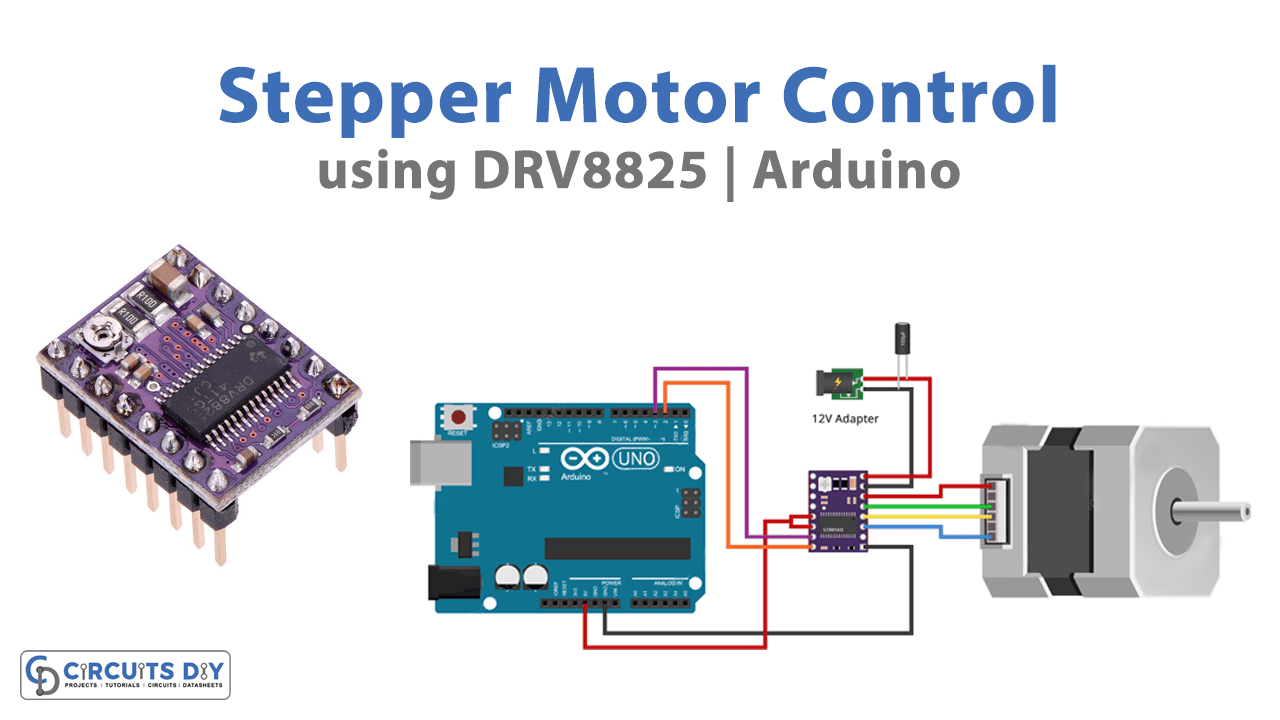

Interfacing a stepper motor with an Arduino board involves connecting the motor's coils to the board's output pins, typically through a motor driver or H-bridge circuit. The motor driver acts as an interface between the Arduino and the stepper motor, providing the necessary current and voltage to drive the motor.

There are several motor driver options available, such as the ULN2003, L298N, and DRV8825, each with different capabilities and specifications. Selecting the right driver depends on your motor type, voltage, and current requirements. Once connected, you can use the Arduino IDE to write and upload code to control the motor's movement.

Programming Stepper Motors Using Arduino

Programming a stepper motor with Arduino involves writing code to control the sequence and timing of electrical pulses sent to the motor's coils. The Arduino IDE provides a user-friendly environment for writing and uploading code to the board.

The most common way to program stepper motors with Arduino is by using the Stepper library, which simplifies the process of controlling the motor's movement. This library provides functions for setting the motor's speed, direction, and position, allowing you to create complex motion profiles with ease.

Stepper Motor Libraries for Arduino

There are several libraries available for controlling stepper motors with Arduino, each offering different features and capabilities. The most popular libraries include the Stepper library, the AccelStepper library, and the EasyDriver library.

The Stepper library is included with the Arduino IDE and provides basic functions for controlling the motor's speed and direction. The AccelStepper library offers more advanced features, such as acceleration and deceleration control, making it suitable for more complex applications. The EasyDriver library is designed for use with the EasyDriver motor driver and provides functions for controlling microstepping and other advanced features.

Power Supply Considerations

When controlling stepper motors with Arduino, it is essential to consider the power supply requirements for both the motor and the Arduino board. Stepper motors typically require a higher voltage and current than the Arduino can provide, necessitating an external power supply.

Ensure that your power supply can deliver the necessary voltage and current to drive the motor without exceeding its rated specifications. Additionally, consider using a separate power supply for the Arduino board to avoid voltage drops and potential damage to the microcontroller.

Troubleshooting Common Issues

When working with stepper motors and Arduino, you may encounter various issues, such as erratic movement, overheating, or insufficient torque. To troubleshoot these issues, start by checking your connections and ensuring that all components are correctly wired and powered.

Next, verify that your code is correctly written and uploaded to the Arduino board. Check for syntax errors, incorrect pin assignments, and other coding issues that may affect the motor's performance. If problems persist, consider testing your components individually to identify any faulty parts.

Advanced Control Techniques

For more sophisticated applications, you may need to implement advanced control techniques, such as microstepping, feedback control, and closed-loop systems. These techniques can improve the precision, efficiency, and stability of your stepper motor control.

Microstepping allows for smoother motion and increased resolution by gradually changing the current in the motor's coils. Feedback control systems, such as those using encoders or Hall-effect sensors, provide real-time feedback on the motor's position, enabling more accurate and responsive control.

Applications of Stepper Motors

Stepper motors are used in a wide range of applications, from 3D printers and CNC machines to robotics and precision instrumentation. Their ability to provide precise control over position and movement makes them ideal for tasks requiring accuracy and repeatability.

In robotics, stepper motors are often used for controlling joints and actuators, enabling precise movement and positioning. In 3D printing and CNC machining, they drive the motion of the print head or cutting tool, ensuring accurate and consistent results. Additionally, stepper motors are used in precision instruments, such as microscopes and telescopes, where precise positioning is critical.

Safety Precautions

When working with stepper motors and Arduino, it is essential to follow safety precautions to prevent damage to components and ensure your personal safety. Always disconnect power before making any connections or modifications to your circuit. Use appropriate heat sinks and cooling methods to prevent overheating of the motor driver and motor.

Ensure that your power supply is within the recommended voltage and current specifications for your motor and driver. Avoid placing any objects in the path of the motor's movement to prevent injury or damage to the motor and surrounding components.

Frequently Asked Questions

What is the difference between unipolar and bipolar stepper motors?

Unipolar stepper motors have center-tapped windings, allowing for simpler control circuits, while bipolar motors have single windings per phase, offering higher torque and efficiency but requiring more complex control circuits.

Can I control multiple stepper motors with a single Arduino board?

Yes, you can control multiple stepper motors with a single Arduino board by using motor drivers for each motor and writing code to control their movement simultaneously.

What power supply should I use for my stepper motor?

The power supply should match the voltage and current requirements of your stepper motor and driver. Ensure that the power supply can deliver sufficient current without exceeding the motor's rated specifications.

How can I improve the precision of my stepper motor control?

To improve precision, consider using microstepping techniques, which increase resolution by gradually changing the current in the motor's coils. Additionally, use feedback control systems to provide real-time feedback on the motor's position.

What are some common issues when working with stepper motors and Arduino?

Common issues include erratic movement, overheating, and insufficient torque. To troubleshoot, check your connections, verify your code, and test components individually to identify any faults.

Are there any safety considerations when using stepper motors?

Yes, always disconnect power before making changes to your circuit, use appropriate cooling methods to prevent overheating, and ensure your power supply matches the motor's specifications. Avoid placing objects in the motor's path to prevent injury or damage.

Conclusion

Controlling stepper motors with Arduino offers a versatile and powerful solution for a wide range of applications, from robotics to precision machinery. By understanding the fundamentals of stepper motor control, interfacing techniques, and programming strategies, you can unlock the full potential of these devices in your projects. Whether you're a hobbyist or a professional, leveraging the capabilities of Arduino and stepper motors will enhance your ability to create precise, efficient, and innovative systems.

For further reading and resources on stepper motor control and Arduino, consider exploring online tutorials, forums, and documentation available on platforms such as Arduino's official website, Instructables, and Stack Exchange. These resources offer valuable insights and guidance for expanding your knowledge and skills in controlling stepper motors with Arduino.

Article Recommendations

- The Untold Wealth Of Kenyas Richest Individual

- Megan Foxs Festive Charm A Christmas To Remember

- Explore Goojara Tocom The Comprehensive Guide To Essential Services